Update Time:2025-06-05

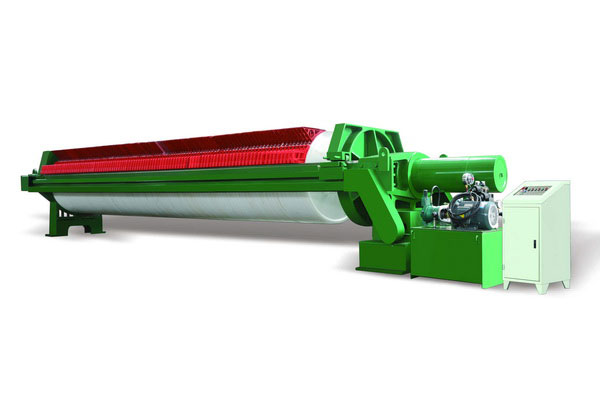

In the world of industrial solid-liquid separation, few machines are as essential and widely used as the Filter Press. Designed to efficiently remove moisture from slurries and other semi-liquid materials, filter presses play a crucial role in industries such as mining, chemical processing, food production, and wastewater treatment. Among the many models available, the Filter Press ZWYB-1000, equipped with Plate Number 80, stands out for its high capacity and performance. As a leading manufacturer, Tianfu Long specializes in delivering durable, high-efficiency filter press systems tailored to meet diverse operational needs.

The ZWYB-1000 Filter Press is engineered to handle large-scale filtration tasks with precision and reliability. Featuring 80 filter plates, this model provides a substantial filtration area, making it ideal for applications requiring high-volume processing and efficient cake discharge. Each unit is built using high-quality polypropylene plates resistant to corrosion and wear, ensuring long-term durability even under harsh conditions.

As a renowned China-based manufacturer, Tianfu Long has built a strong reputation for combining advanced engineering with cost-effective production. The company adheres to international quality standards such as ISO 9001 and CE certification, ensuring that every filter press meets stringent performance and safety benchmarks. With years of expertise in hydraulic and automated filtration systems, Tianfu Long continues to innovate and expand its product offerings to serve global markets.

One of the key strengths of Tianfu Long is its ability to offer custom solutions. As a dedicated Custom Filter Press Supplier, the company understands that no two industrial processes are the same. Whether it’s adjusting plate size, modifying pressure settings, or integrating automation features, Tianfu Long works closely with clients to design tailor-made filter press systems that align perfectly with their workflow and production goals.

The Filter Press Plate Number 80 configuration in the ZWYB-1000 model is particularly popular among customers seeking a balance between throughput and compact installation. This system is capable of producing dry cakes with low moisture content, significantly reducing disposal costs and improving overall process efficiency. Its robust hydraulic system ensures consistent pressing force, while the optional automatic plate shifter enhances productivity by minimizing manual labor.

Tianfu Long also places great emphasis on after-sales service and technical support. From installation guidance to maintenance training and spare parts supply, the company ensures that clients receive comprehensive assistance throughout the lifecycle of their equipment. This commitment to customer satisfaction has helped Tianfu Long establish a loyal client base across Asia, Africa, South America, and beyond.

For businesses looking for a reliable Filter Press Manufacturer that can deliver both standard and custom configurations, Tianfu Long is a trusted partner. The company's extensive R&D capabilities, combined with scalable manufacturing operations, allow it to cater to small-scale startups and large industrial complexes alike.

Moreover, sustainability is becoming increasingly important in industrial operations, and Tianfu Long is committed to developing eco-friendly solutions. Their filter presses help reduce water consumption and waste volume, supporting green manufacturing initiatives and compliance with environmental regulations.

With a well-established global distribution network and multilingual customer service team, Tianfu Long ensures timely delivery and responsive communication for clients worldwide. Whether you need a single unit for a pilot plant or an entire line of filter presses for a new facility, Tianfu Long delivers customized, high-performance solutions that match your exact requirements.

In conclusion, Tianfu Long is more than just a manufacturer—it is a leader in innovative, custom filtration technology that empowers industries to operate more efficiently and sustainably. By focusing on quality, customization, and customer care, the brand continues to set new standards in the global filter press market.